Localised Pressure Impregnation

'Localised Pressure Impregnation' accurately applies the impregnation sealant directly to the area of porosity that leaks using an easy to use, very effective and low cost hand held pressure impregnation gun. The process uses a range of rubber washers from which the most appropriate is selected and positioned on the casting to match the precise point of porosity. The gun is then applied to pressure impregnate the porosity with sealant with the operation completed by rapid curing - typically the process takes one minute and the casting can be re-tested in as little as 30 minutes. Significantly, because the sealant cures inside the casting porosity and not on its surface, there is no surface residue. There is also no need for subsequent washing and heat curing.

Identification of the specific area of porosity in a casting that causes a leak is vital information for the foundries to make improvements to their casting process and at the same time allows 'localised' impregnation to be carried out, resulting in greater efficiencies and much lower costs. Conventionally, impregnation has been undertaken by total immersion of large baskets of castings in sealant in a vacuum and pressure vessel followed by washing off the excess sealant in cold water, before curing the castings in 90°C hot water. This treats the part in its entirety, rather than simply targeting the specific area of porosity and is consequently wasteful of chemicals, water and energy.

Localised Impregnation eliminates the need for large capital investment in conventional equipment and significantly reduces the cost to recover leaking castings. Savings of over 90% compared to conventional impregnation equipment are possible. The risk of sealant contamination in threads, oil ways and other internal galleries and of corrosion and discoloration of castings - common problems experienced with impregnation equipment to date - are also removed. Part assembled castings can be sealed using localised impregnation, which is not possible through conventional equipment. Localised Impregnation also enables a higher recovery rate of leaking castings to be achieved compared to conventional equipment. A recovery rate as high as 100% is common as a result of a number of factors including the ability with Localised Impregnation to tailor the sealant to the type of porosity on a part-by-part basis. Significantly, there is no wash-out of impregnation sealant from the porosity during conventional washing and curing, resulting in a better quality seal.

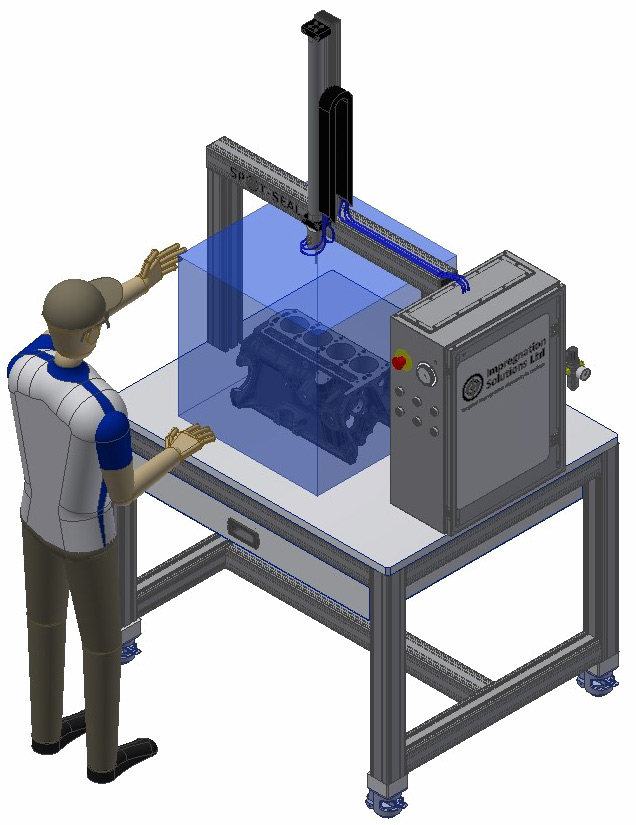

Bench-mounted and automated systems are also available for volume production.

Automatic Spot-Seal Impregnation system.